tlhaloso

PE sintered filthara element, le boleng bo phahameng bao e seng chefo, tasteless ultra-high molek'hule boima polyethylene e le thepa e ka sehloohong e tala, ka mokhoa oa saense formula sintering, ha mocheso sebetsa ka 80oC tensile matla a khatello ea matla, ha ho bonolo ho deformation, ho hanyetsa tšusumetso, acid e matla, alkali e matla. E khetholloa ke kabo e tšoanang ea li-microholes. Boholo ba pore bo ka laoloa ka bonyane ba 1 micron ho isa ho 140 micron pakeng tsa li-apertures tse leshome tse fapaneng tsa litlhaloso tse fapaneng tsa filthara ea tube, e ka hloekisoa, ho feta 1 micron likaroloana tse tiileng, ho hloekisa ka mokhoa o hlakileng le o hlakileng, bakeng sa 1 micron ho ea ho 0.5 micron particles, e nyenyane feela ea ho sefa, nakoana ka mor'a ho sefa lesela le tšesaane ka mor'a ho sefa. Tlas'a boemo ba 70oC, e na le khanyetso e matla ea khoholeho ea lihlahisoa tsa tlhaho tse kang mafura le ether ntle le ntho leha e le efe ea botsofali.

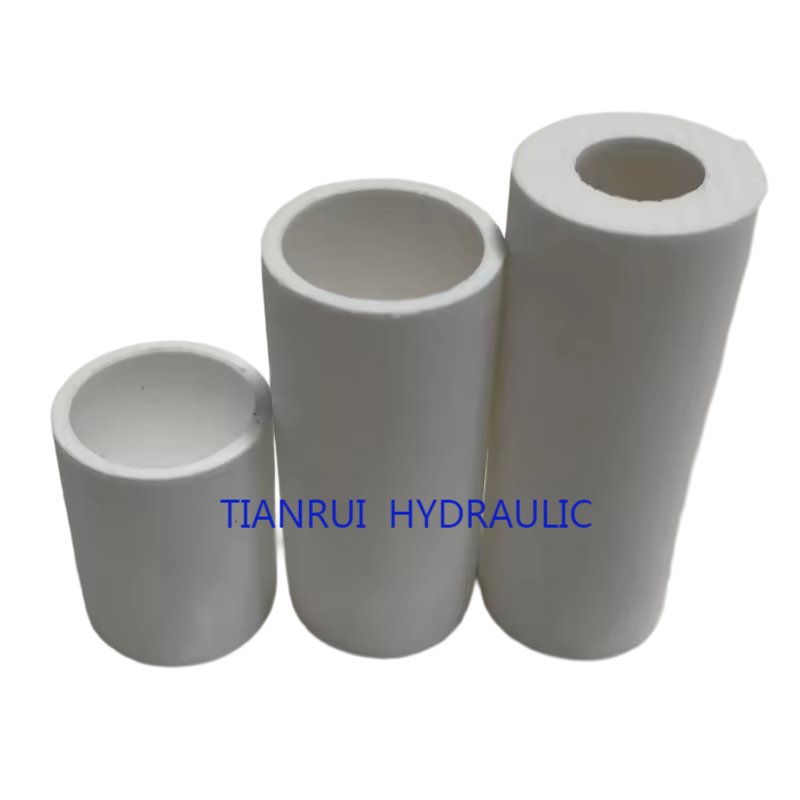

Phetoho BUSCH 0532140157 Litšoantšo

Mehlala eo re fanang ka eona

| lebitso | Sefate sa PTFE |

| Kopo | mokelikeli Tsamaiso |

| Mosebetsi | mohloekisi |

| Sefa thepa | PTFE |

| mofuta | sintering |

| Boholo | tloaelo |

Melemo ea PE sintered filter element:

1. Sekhahla se seholo sa phallo: porosity e phahameng;

2. Ponahalo e boreleli: sebaka se boreleli, e le hore litšila li se ke tsa e-ba bonolo ho li khomarela, ho hlatsoa ho bonolo haholoanyane;

3.Bokhoni bo matla ba ho thibela litšila: ho nepahala ha filthara ea ka ntle e nyane le e kholo kahare ho etsa hore litšila li se ke tsa lula sebakeng sa sefa;

4.Seretse se ka hatelloa ho fihlela ho 70% ea metsi;

5. Ts'ebetso e ntle ea litšenyehelo: karolo ea filthara e na le ts'ebetso e felletseng e felletseng le theko e tlase, e loketseng kalafo ea metsi le ts'ireletso ea tikoloho ea likhoerekhoere; Tšebeliso ea metsi a tsosolositsoeng, ho sefa lihlahisoa tsa lik'hemik'hale le maemo a mang a maholo a phallo;

6.E hanana le kutu e matla ea asiti le alkaline, e hananang le ho qhibiliha ha li-solvents;

7.Matla a eona a babatsehang le ho hanyetsa ho apara ho tiisa bophelo ba eona ba tšebeletso.

8. Matla a matle, sefahla ha se bonolo ho robeha;

9. Ha ho ketsahalo ea ho pola;

10. Ho hanyetsa khatello e matla;

Sebaka se Sebelisitsoeng:

(1) Indasteri ea lik'hemik'hale - Ho hlahisa metsi a nepahetseng ka mokhoa o nepahetseng joalo ka silicon sulfate hydrogen peroxide liquid alkali phosphate methanol ethanol alcohol sulfur aluminium decolorization activated carbon separation.

(2) Indasteri ea meriana - tlhoekiso ea metsi a decolorization reverse osmosis ion exchanger ultrafiltration e joalo ka ho nepahala pele ho kalafo mochini oa botlolo ea metsi tlhoekiso e kholo ea infusion ea nale ea meriana e lipakeng decarbonization filtration fermentation mokelikeli oa molomo oa mokelikeli oa setso oa China biopharmaceutical

(3) Indasteri ea lijo - tlhoekiso ea metsi a metsi a liminerale, biri, joala le lino

(4) Indasteri ea ts'ireletso ea tikoloho - phepelo e kholo ea metsi a khutsitseng ente ea khase ea tlhaho ea tlhoekiso ea phepelo ea metsi le liindasteri tse ling tse ngata.

Boemo ba Khoebo

MOLEMO OA RONA

Litsebi tsa Filtration tse nang le boiphihlelo ba lilemo tse 20.

Boleng bo tiisitsoe ke ISO 9001:2015

Sistimi ea profeshenale ea data ea tekheniki e netefalitse ho nepahala ha filthara.

Tšebeletso ea OEM bakeng sa hau le ho khotsofatsa tlhoko ea mebaraka e fapaneng.

Hlahloba ka hloko pele o pepa.

TŠEBELETSO RONA

1.Consulting Service le ho fumana tharollo bakeng sa mathata leha e le afe a indasteri ea hau.

2.Designing le tlhahiso e le kopo ea hao.

3.Hlahloba 'me u etse litšoantšo e le litšoantšo kapa lisampole tsa hau bakeng sa netefatso ea hau.

4.Kamohelo e mofuthu bakeng sa leeto la hau la khoebo ho ea fekthering ea rona.

5.Perfect ka mor'a-thekiso tšebeletso ho laola qabang ea hao

LIHLAHISO TSA RONA

Lifilimi tsa Hydraulic le likarolo tsa sefa;

Sefa element cross reference;

Notch wire element

Sefahla sa pompo ea vacuum

Li-filters tsa terene le lisebelisoa tsa sefa;

Mokelli oa lerōle filthara khatriji;

Sesefa sa tšepe e sa hloekang;

Sebaka sa Kopo

1. Metallurgy

2. Railway Internal combustion engine le jenereithara

3. Indasteri ea Marine

4. Thepa ea Mechanical Processing

5. Petrochemical

6. Lesela

7. Elektronike le Meriana

8. Matla a mocheso le matla a Nyutlelie

9. Enjene ea koloi le mechine ea Kaho